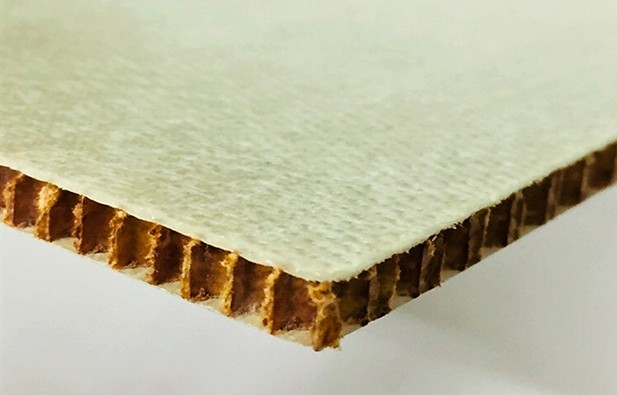

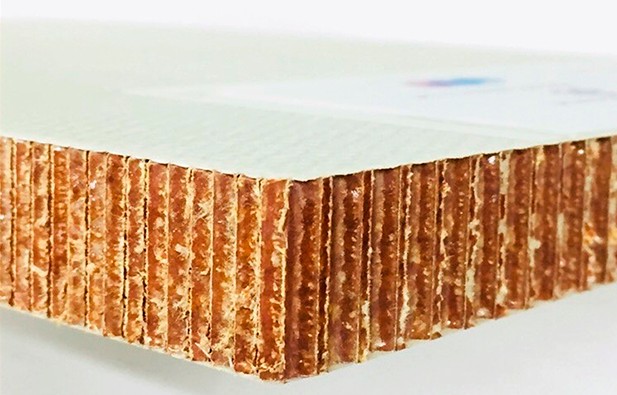

FULLY MANUFACTURED HONEYCOMB PANELS

Honeycomb panel is one of the most important engineering innovations of composite industry. Tulpar Interior Group uses honeycomb panels in aircraft and vessel cabins taking the following advantages of this product:

- lightweight;

- high stiffness;

- static strength is 20-40% higher;

- longitudinal compression stability is 2-4 times as much;

- quantity of a component parts is reduced by a factor of 3-4;

- component surface is more smooth;

- thermal properties are 3-5 times as much;

- acoustic performance has increased three-fivefold.

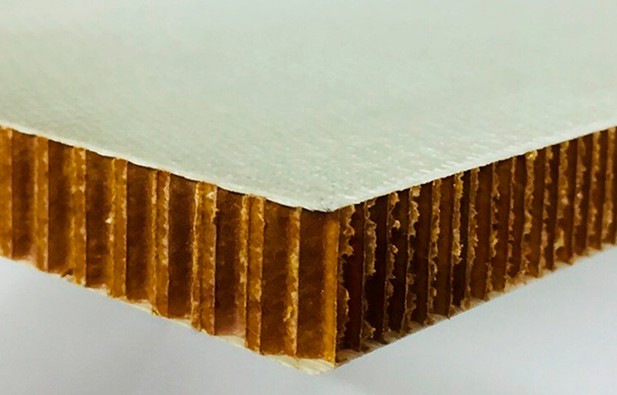

THREE-LAYER HONEYCOMB PANEL

Specifications:

- 5 mm thick;

- from 1220 mm up to 2440 mm long (at customer request);

- panel density: 280 kg/mЗ;

- panel weight: 4.168 kg.

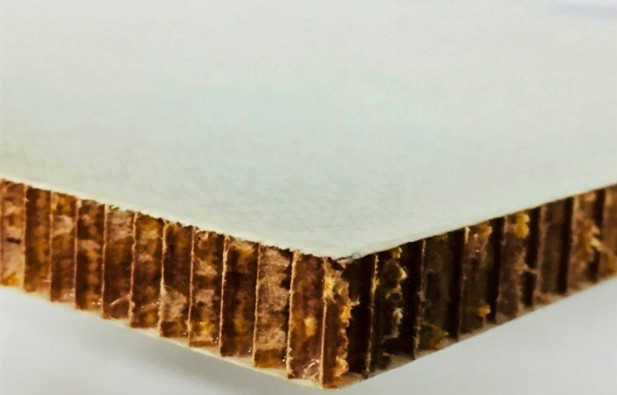

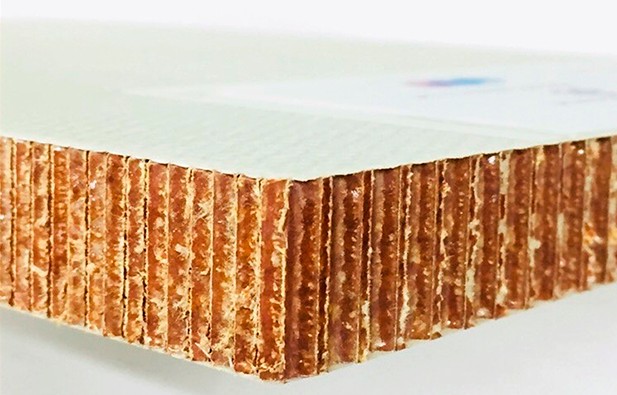

THREE-LAYER HONEYCOMB PANEL

Specifications:

- 10 mm thick;

- from 1220 mm up to 2440 mm long (at customer request);

- panel density: 164 kg/mЗ;

- panel weight: 4.9 kg.

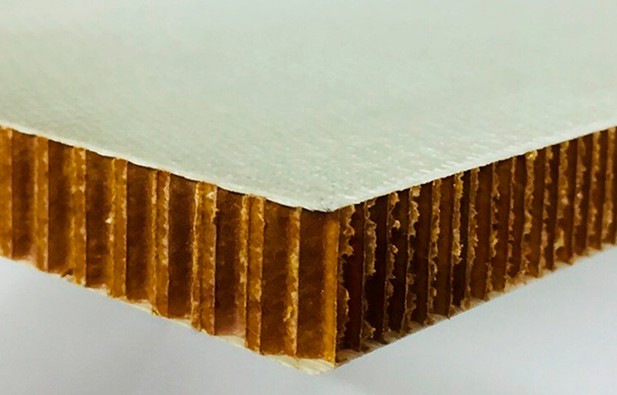

THREE-LAYER HONEYCOMB PANEL

Specifications:

- 15 mm thick;

- from 1220 mm up to 2440 mm long (at customer request);

- panel density: 125 kg/mЗ;

- panel weight: 5.6 kg.

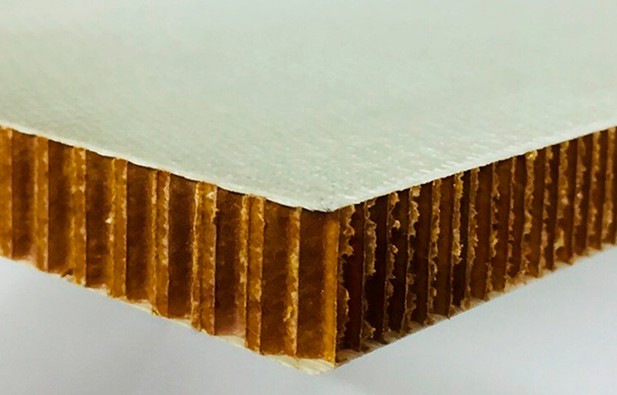

THREE-LAYER HONEYCOMB PANEL

Specifications:

- 20 mm thick;

- from 1220 mm up to 2440 mm long (at customer request);

- panel density: 106 kg/mЗ;

- panel weight: 6.31 kg.

THREE-LAYER HONEYCOMB PANEL

Specifications:

- 25 mm thick;

- from 1220 mm up to 2440 mm long (at customer request);

- panel density: 95 kg/mЗ;

- panel weight: 7.07 kg.

Tulpar Interior Group’s pre-production activities included:

1. Research-and-development stage;

2. Designed and implemented the following manufacturing processes:

- “Panel production from T-15 with binder by means of stove forming”;

- “Panel production from T-15 with binder by means of press forming”;

- “Panel production from carbon prepreg”;

- “Solid panel production from glass or carbon prepreg”;

- “Production of panels with ornamental plastic by means of thermoforming”.

3. Conducted the following type tests of three-layer honeycomb panels:

- burning tests i.a.w. aviation standards at testing center of the Russian Institute of Aviation Materials;

- flammability tests of construction materials i.a.w. national state standard no. 30244-93 at testing center “Kazpozhtest” (Rostest LLC);

- slow spread of flame test i.a.w. International Code for Application of Fire Test Procedures 2010 (2010 FTP Code) at testing center “NWRC Test” LLC

4. Certified three-layer honeycomb panel production in the sphere of fire safety (certificate no. НСОПБ.RU.ЭО.ПР029.Н.00003);

5. Started producing flat or curved three-layer honeycomb panels from 5 up to 25 mm thick and from 95 up to 250 kg/m3 dense.